Products

Your all-inclusive solution

All Products

Download our catalog

Get our Catalog

Applications

The Electron-Multiplying CCD (EMCCD) is a CCD camera to which is added a special electron multiplication output register. It is designed to practically eliminate the detrimental effect of the readout noise intrinsic to imaging devices, making them significantly more sensitive.

Though generating less noise goes a long way to increase a camera’s sensitivity, an important part of the equation is also to maximize how efficiently each photon received by the EMCCD is converted to signal on the image. The key to achieving this goal is to carefully consider the different components interacting with light inside the camera; the sensor and the optical window.

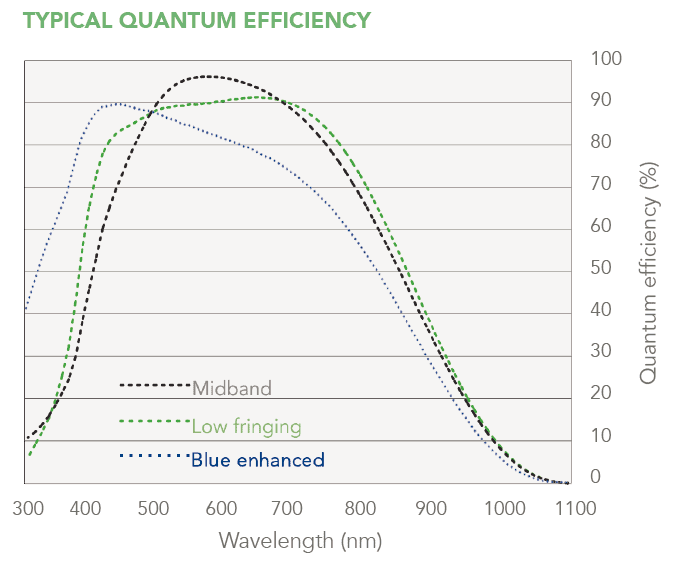

The EMCCD’s silicon sensor chip is designed and built to maximize the number of photoelectrons generated when exposed to light. However, the efficiency of the conversion of photons to photoelectrons depends on the signal’s wavelength.

A measure of this conversion efficiency by wavelength is the quantum efficiency (QE) curve. While the sensor itself has a strong influence on the QE, another factor is the sensor anti-reflection (AR) coating. A specific sensor can be manufactured with different coatings which have a strong impact on the QE curve by minimizing the reflections on the sensor’s surface. Choosing the sensor coating that maximizes the QE for the wavelengths of interest results in more signal detected by the camera.

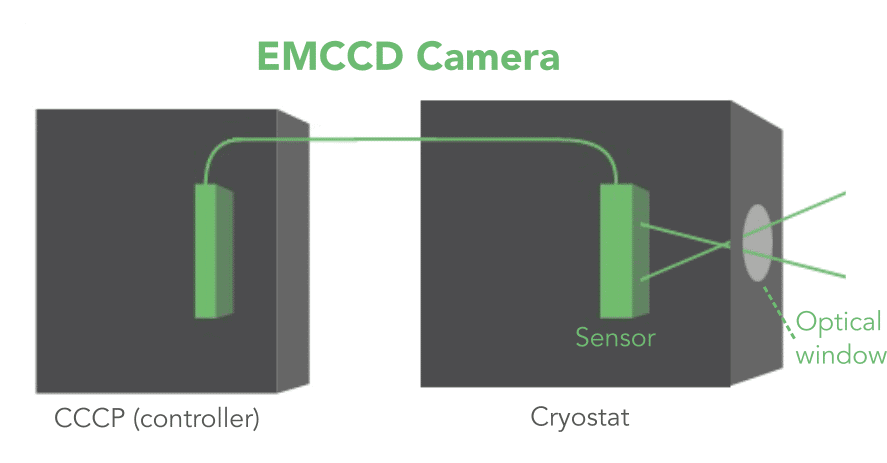

The EMCCD sensor is housed inside a cryostat, which is an isolated enclosure built to enable deep cooling of the silicon chip and to protect it from the external environment. An optical window is used to create an optical path from the outside of the camera to the sensor.

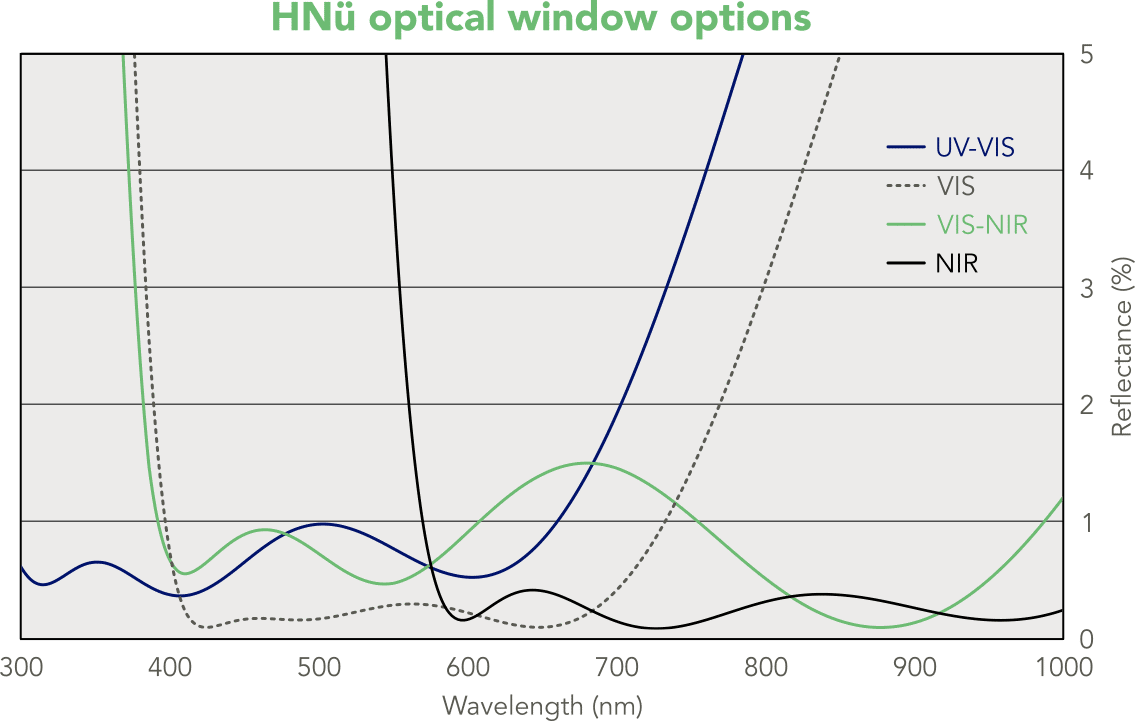

To maximize light transmission through the optical window, an AR coating is applied to the component. These coatings have specific reflectance values at each wavelength. It is important to choose the appropriate coating to minimize reflectance at the wavelengths of interest.

Nüvü’s EMCCDs feature standard C-mount threading to add optical components such as a lens (not included with the camera). The reflectance properties of the additional components should follow the same rule as that of the EMCCD’s optical window; minimizing reflectance at the wavelengths of interest.